Our Company

BEST PERFORMANCE SINCE 1987.

More than 30 years of commitment, competence, and expertise have turned Konrad Friedrichs GmbH (KF) into one of the world wide leading manufacturers of cemented carbide rod material. KF was founded in 1987 in Kulmbach/ Germany – today an enterprise of more than 200 employees producing up to 1000 tons of carbide rods annually.

Today’s product range includes carbide rods without and with coolant ducts (straight or helical twisted with up to 6 coolant ducts), as well as cut to length material, preformed special parts and custom-made items. A comprehensive quality assurance System – certified to DIN EN ISO 9001:2008 – ensures high-class standards of our products.

Our carbide grades K40UF, K40XF, K44UF, K88UF, K55SF, K6UF and K5UF set worldwide standards in the area of tungsten carbide cutting tools. To meet the constantly rising demands from tool manufacturers we have concentrated our R&D activities on the development of new innovative cemented carbide grades. In particular hardness and toughness of our materials are adapted to the increasing complexity of cutting processes, e. g. highly heat-resisting steels, super-alloys and CFRP, as well as High Performance and High Speed Cutting.

Together with our partners we established a worldwide sales network at all 5 continents. As a medium-sized company with slender structure we react fast and flexible to our customer’s requirements. Based on partnership, we compile suitable solutions for the respective needs.

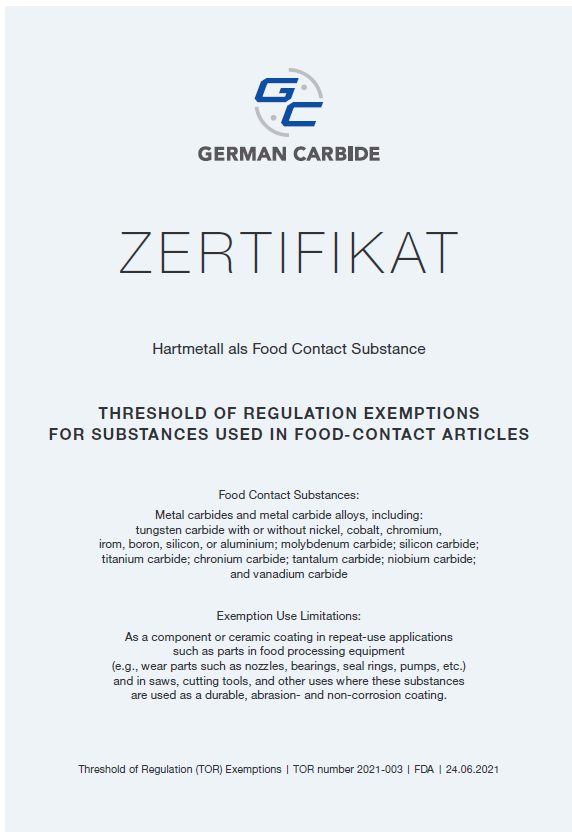

Certification

Basis for sustainable production of high-quality sub-micrometer carbide structures is our DIN EN ISO 9001:2015 certification. Traceability and reproducibility of our products and processes are always guaranteed by a complete documentation.

Increase of energy efficiency, lower energy costs, less CO2 emission and thereby relieving the environment – by certification to DIN EN ISO 50001 we want to make our contribute to environmental protection.